Building Big in a Small Country: The Secrets Behind Singapore’s Public Housing

In the heart of Singapore, a remarkable story unfolds—how a small nation is mastering the art of large-scale construction. This blog explores the intricacies of ‘Building Big in a Small Country’, revealing the innovative techniques and challenges faced in creating public housing that meets the needs of its rapidly growing population.

Table of Contents

- Introduction

- New Housing Areas in Singapore

- The Role of Technology in Construction

- Sustainability in Public Housing

- Community Engagement During Construction

- The Future of Housing in Singapore

- FAQ

Introduction

In Singapore, the concept of home goes beyond mere walls and roofs. It’s about creating a community where families thrive and individuals find solace. With a population that continues to grow, the demand for housing has surged, prompting the need for innovative solutions. One of the most effective methods has been the adoption of precast technology, a game-changer in the construction landscape. This technology has not only streamlined the building process but also maximized the use of limited land resources in this small yet vibrant country.

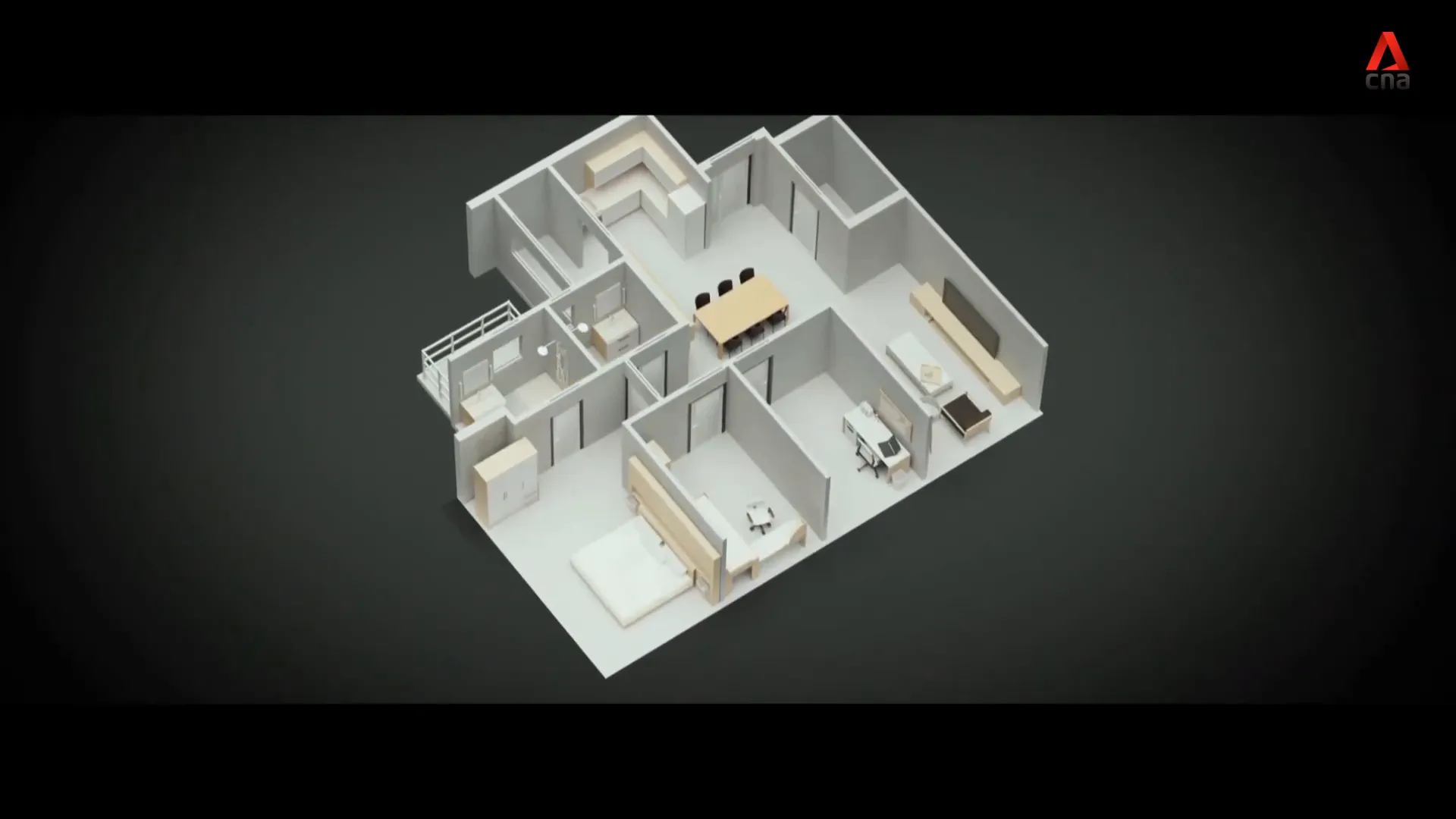

Which Part of Your Home is Precast?

When you step into a public housing flat in Singapore, you’re experiencing a marvel of modern engineering. The majority of these homes are constructed using precast components, which include everything from walls and columns to staircases and even toilets. Essentially, precast technology allows for the fabrication of building elements in a controlled environment, ensuring quality and efficiency.

For instance, the kitchen and bathroom units are typically precast, providing homeowners with ready-to-install modules that save time and labor on-site. This means that while you may see a beautiful flat, there’s a complex system of prefabricated parts working seamlessly behind the scenes to make it all come together.

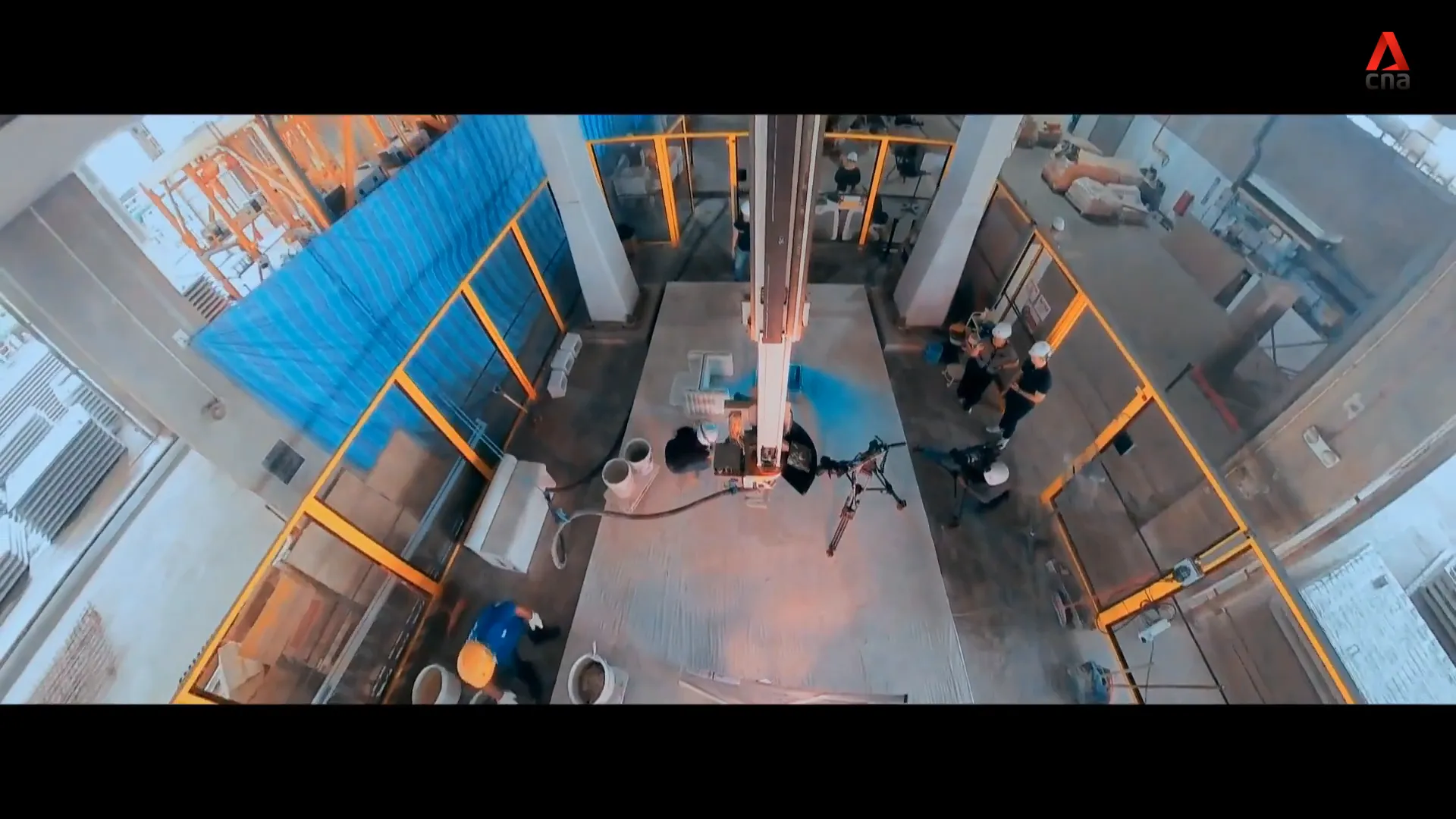

Singapore’s Latest Precast Plant

Singapore’s commitment to advancing construction technology is evident in its latest precast plant, which is primarily automated. This facility is capable of producing essential components such as walls and bomb shelters, underscoring the nation’s focus on safety and efficiency. Despite the advanced technology, the plant’s output is limited to around 2,500 flat units annually due to space constraints.

To combat the challenges of limited land, the plant employs specially designed racks for the storage of modular parts. This innovative approach ensures that even within a small footprint, the production process remains efficient and organized.

HDB Precast Component Supplier in Malaysia

To supplement local production, Singapore collaborates with a large precast plant located in Malaysia. Spanning 36 hectares, this facility is one of the biggest suppliers of precast components for HDB projects. It specializes in prefabricated volumetric construction (PPVC), which can be likened to assembling Lego bricks to form a building.

Components produced here include both 2D and 3D elements, ranging from facades to floor slabs. These parts are then transported back to Singapore, where they undergo final assembly and fit-out processes. This collaboration with Malaysia not only helps meet the soaring demand for housing but also alleviates some of the pressure on Singapore’s limited land resources.

How Precast Components are Made

The process of creating precast components is meticulous and time-consuming but yields significant benefits in terms of quality and efficiency. For instance, producing a kitchen unit requires the creation of a customized steel mold, a process that can take anywhere from four to six weeks. Once the mold is ready, steel reinforcement bars are inserted to enhance strength, followed by the pouring of concrete. After curing, these components are stored until they are needed on-site.

Transportation of these precast elements is a well-coordinated effort, with around 130 trailers making the journey across the causeway daily. Upon arrival in Singapore, these components undergo final adjustments at fit-out yards, ensuring they are ready for swift installation at construction sites.

New Housing Areas in Singapore

As Singapore continues to grow, the demand for new housing areas has become increasingly vital. The Housing and Development Board (HDB) is committed to expanding public housing to meet these needs. New developments are strategically planned in various regions, ensuring accessibility and convenience for residents.

These new housing areas often incorporate modern amenities such as parks, schools, and community centers, fostering a sense of belonging and community. With careful planning, Singapore can ensure that every new housing project contributes positively to the urban landscape.

Challenges of Building BTOs

Building new Build-To-Order (BTO) flats in Singapore is not without its challenges. The limited land available necessitates innovative solutions. Often, construction sites are located in densely populated areas, complicating logistics and requiring careful coordination.

One major challenge is dealing with existing infrastructure. Many sites may have old structures that need to be demolished, which can significantly delay the construction process. Additionally, the proximity to existing residential buildings means that noise and disruption must be minimized, which adds another layer of complexity to the construction timeline.

Other Related Articles:

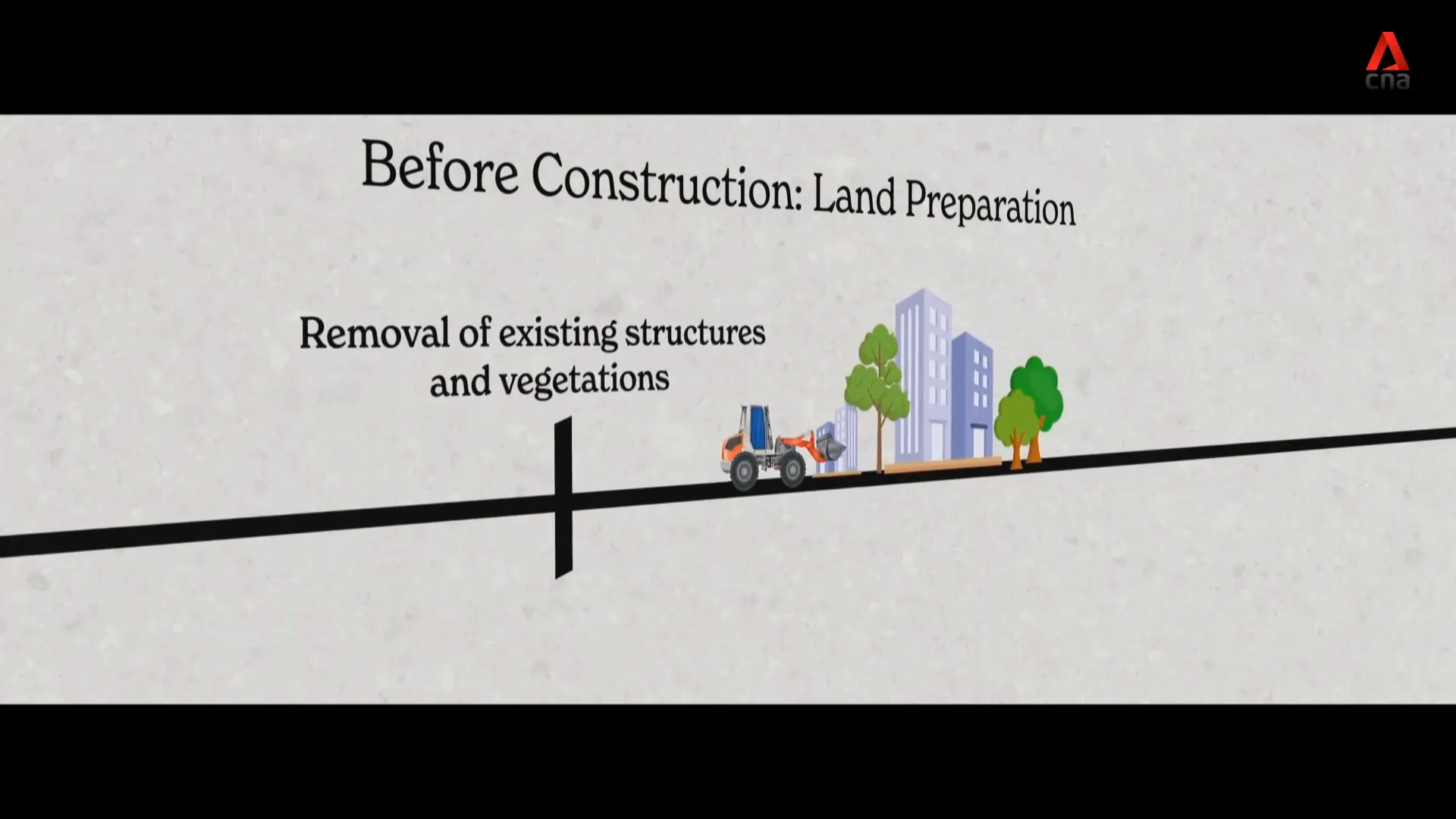

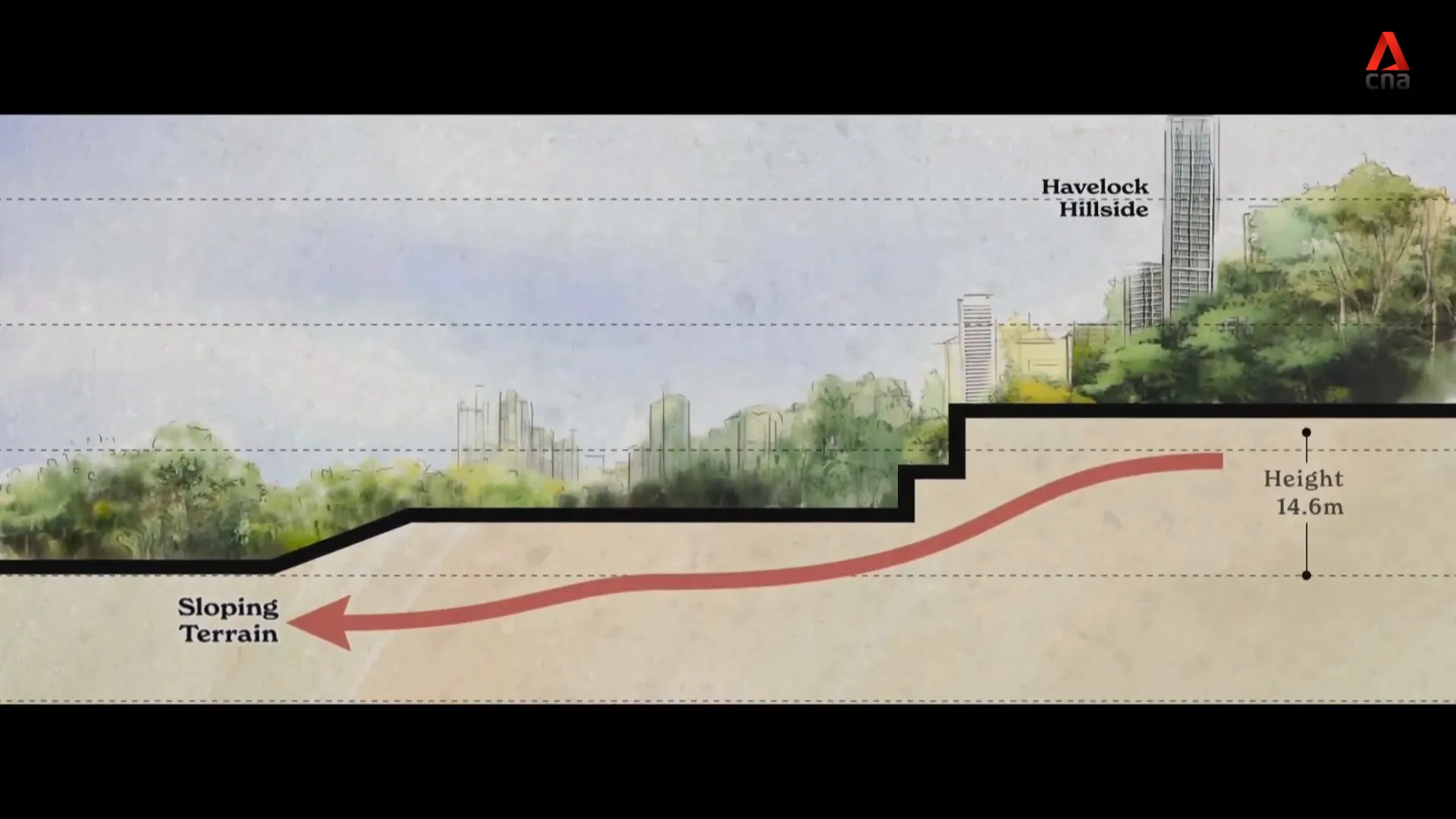

What It Takes to Build on Greenfield

Building on greenfield sites presents unique opportunities and challenges. These areas, which have not previously been developed, allow for more flexibility in design and planning. However, extensive land preparation is required before construction can commence.

This includes clearing vegetation, conducting environmental assessments, and ensuring that the land is stable for building. Engineers meticulously evaluate the soil conditions to ensure the foundations will support the structures. This process can take up to two and a half years, reflecting the importance of careful planning.

What is 3D-Concrete Printing?

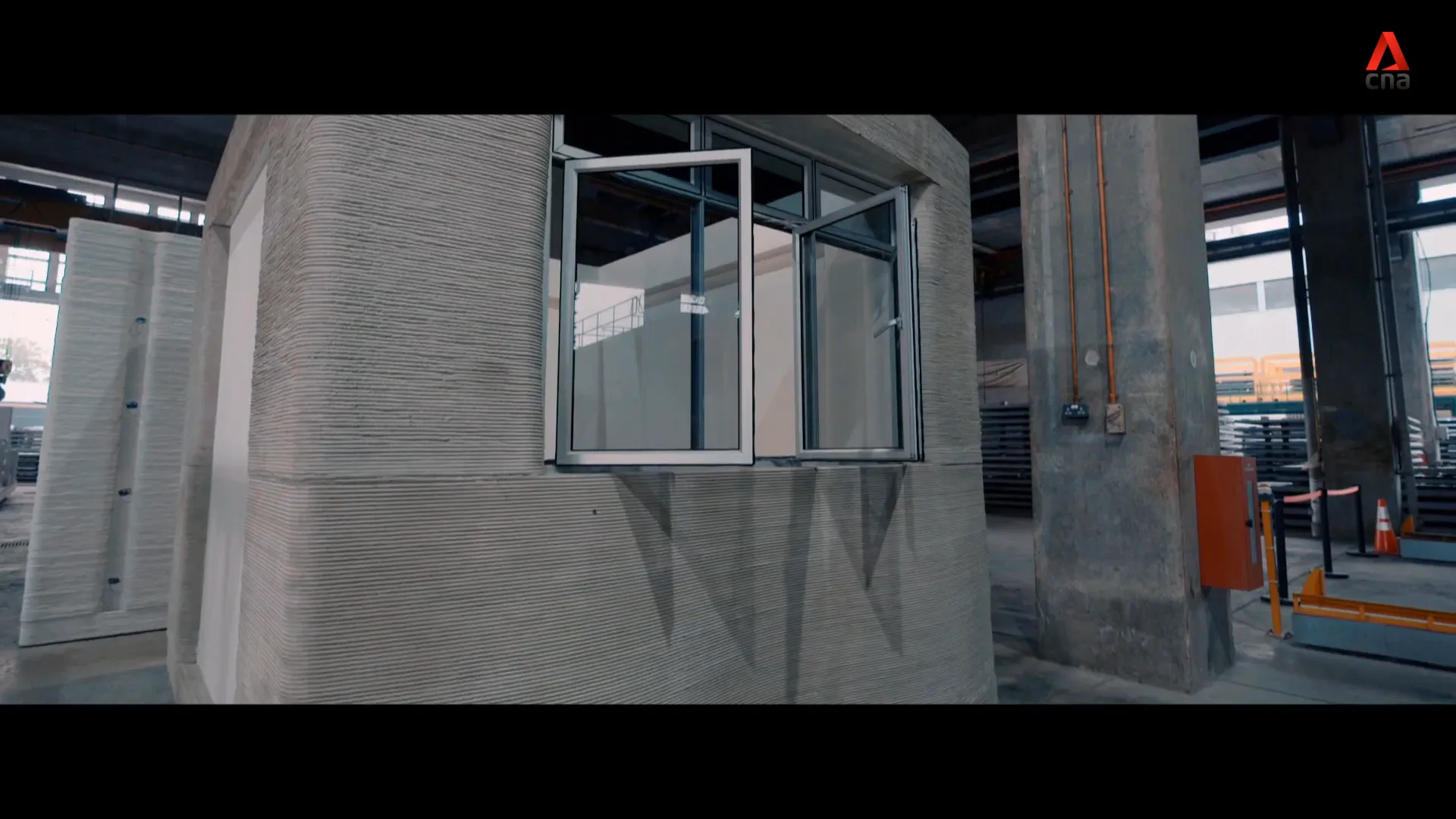

3D-concrete printing is revolutionizing construction in Singapore. This innovative technology allows for the rapid production of building components with remarkable precision. A typical precasting process can take weeks, but with 3D printing, components can be created in just hours.

The largest 3D concrete printer in Southeast Asia showcases this technology’s potential. By reducing labor requirements and construction time, 3D printing addresses some of the pressing challenges faced by the construction industry, particularly the shortage of skilled workers.

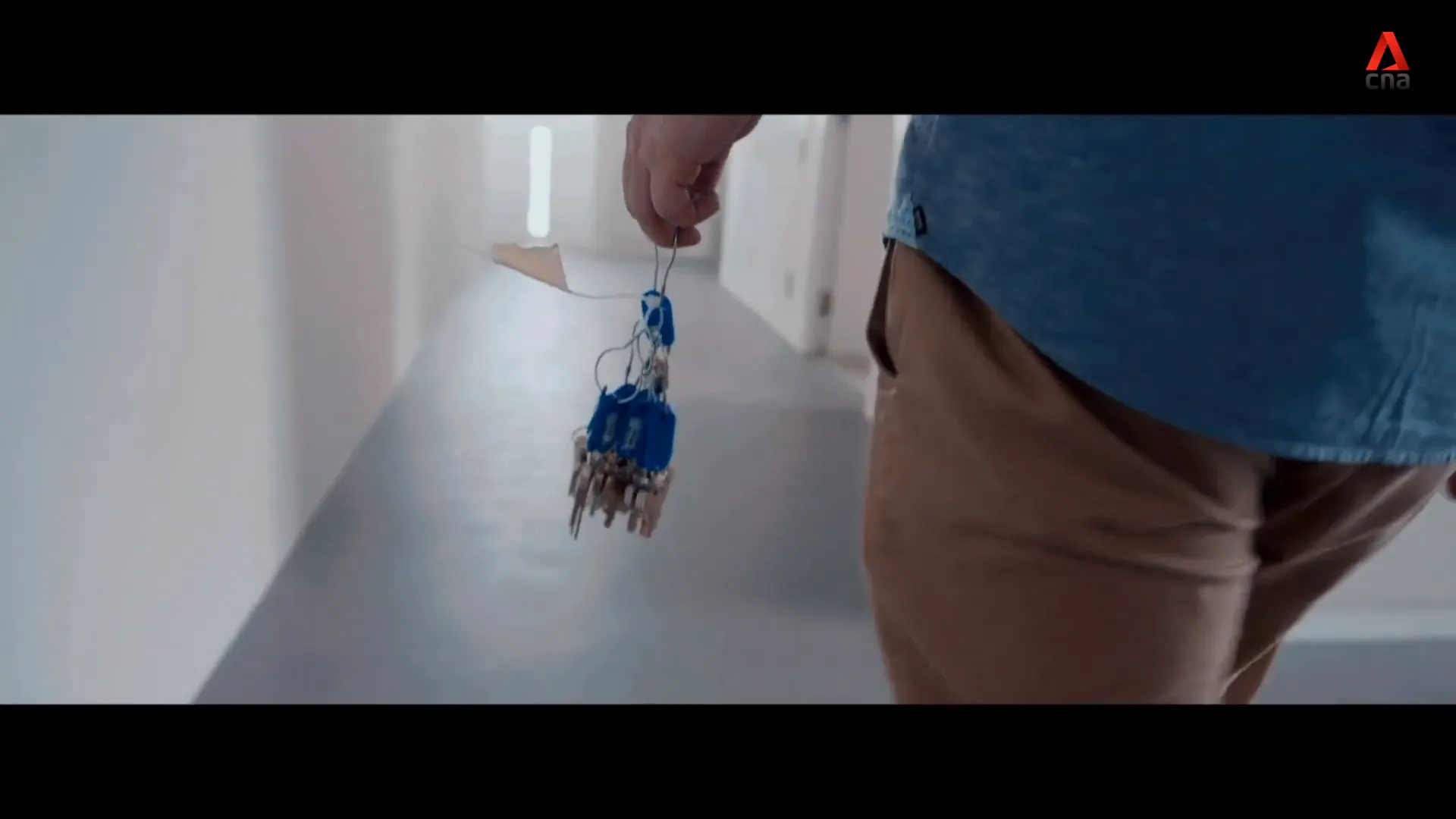

Before Homeowners Receive Their Keys

Before homeowners can move into their new flats, a rigorous inspection process takes place. This ensures that every unit meets the high standards set by the HDB. Inspection teams carefully assess each unit, checking for any defects or issues that need to be addressed.

Typically, inspectors evaluate 12 to 15 units per day, documenting any concerns and communicating with contractors for timely resolutions. This meticulous process ensures that when residents finally receive their keys, their new homes are in perfect condition and ready for occupancy.

The Role of Technology in Construction

In the rapidly evolving landscape of construction, technology plays a pivotal role in shaping how we build. Singapore has embraced various innovative technologies that enhance efficiency, safety, and sustainability in public housing projects. One such advancement is the autonomous tower crane, which streamlines the lifting and placement of precast components. This technology minimizes human error and increases productivity, allowing construction teams to focus on other critical tasks.

Moreover, the integration of 3D printing technology is revolutionizing the industry. With the capability to produce building components in a fraction of the time traditionally required, this method not only saves time but also addresses labor shortages. For instance, what once took four to six weeks to precast can now be accomplished in just hours. The potential for 3D printing to create intricate designs with precision opens up new possibilities for architectural innovation in public housing.

Sustainability in Public Housing

Sustainability is at the forefront of Singapore’s public housing initiatives. The Housing and Development Board (HDB) is committed to creating eco-friendly living spaces that not only cater to the needs of the residents but also minimize environmental impact. This includes incorporating green building standards into new developments, using sustainable materials, and implementing energy-efficient systems.

Furthermore, public housing projects are designed with the environment in mind, often integrating green roofs and vertical gardens. These features not only enhance the aesthetic appeal but also contribute to biodiversity and help regulate temperature, making urban living more sustainable. The concept of “Building Big in a Small Country” is not just about maximizing space; it’s also about doing so responsibly and sustainably.

Community Engagement During Construction

Engaging the community during the construction process is crucial for the success of public housing projects. The HDB actively seeks feedback from residents and stakeholders to ensure that new developments meet their needs and expectations. This engagement helps to foster a sense of ownership and belonging among residents, making them feel part of the community.

Constructing new housing in close proximity to existing homes can lead to concerns from residents about noise and disruption. The HDB works diligently to address these issues, often modifying designs based on community feedback. For instance, if residents express concerns about the placement of facilities like bin centers, the design may be revised to mitigate their impact, demonstrating a commitment to community welfare.

The Future of Housing in Singapore

The future of housing in Singapore is bright, characterized by innovation, sustainability, and community-centric designs. As the population continues to grow, the HDB is exploring new methods to increase housing supply while maintaining quality and livability. This includes the development of smart homes equipped with advanced technologies that enhance the living experience.

Moreover, the integration of artificial intelligence and data analytics into construction processes is set to revolutionize the industry. These technologies will enable better planning, resource allocation, and project management, ultimately leading to faster and more efficient construction timelines. The push towards vertical living solutions—building higher rather than wider—will also continue, maximizing land use while providing residents with stunning views and modern amenities.

FAQ

What is precast technology?

Precast technology involves manufacturing building components in a controlled environment before transporting them to the construction site for assembly. This method enhances efficiency and quality while reducing construction time.

How does Singapore address land scarcity in housing development?

Singapore utilizes innovative construction techniques, such as precast components and 3D printing, to maximize land use. The HDB also explores brownfield and greenfield developments to create new housing areas.

What role does community feedback play in public housing projects?

Community feedback is vital for ensuring public housing projects meet residents’ needs. The HDB actively engages with stakeholders to gather input and make necessary design modifications.

How is sustainability incorporated into public housing?

Sustainability is a key focus in public housing, with the integration of green building standards, energy-efficient systems, and eco-friendly materials. Projects often feature green roofs and vertical gardens to enhance environmental quality.

What technologies are shaping the future of housing in Singapore?

Technologies like autonomous cranes and 3D printing are transforming construction efficiency. The integration of AI and data analytics is also expected to enhance project planning and execution in the future.

Disclaimer: This information is provided for informational purposes only. PropsBit.com.sg does not endorse or guarantee its relevance or accuracy concerning your situation. While careful efforts have been taken to ensure the content’s correctness and reliability at the time of publication, it should not replace personalized advice from a qualified professional. We highly recommend against relying solely on this information for financial, investment, property, or legal decisions, and we accept no responsibility for choices made based on this content.